Every Henry Ford has a James J. Couzens quietly making him a legend. Every Warren Buffett has his Charlie Munger. Every Jagger has a Richards and every Paul a John. So, too, it was true in January of 2008 when Custom Powder Systems found its perfect complement in Integrated Containment Systems. Prior to this conscious coupling, they were two separate companies halfway across the country from each other. Both were doing a good job, but each was missing the magic piece that made today’s whole infinitely greater than the sum of their previous parts.

This first meeting was in North Carolina where Dale “Mac” McIntosh, President of Custom Powder Systems, was looking for a glovebox that could handle radioactive materials for the nuclear power industry. Custom Powder had the powder and system part down, but they needed someone who understood nuclear side of it for the glovebox. This is where Russ Krainiak comes in.

“Russ did as good a presentation as I’ve ever seen. The room was spellbound. It was technical, specific, and right on. They were mesmerized.”

Dale “Mac” McIntosh, President, Custom Powder Systems

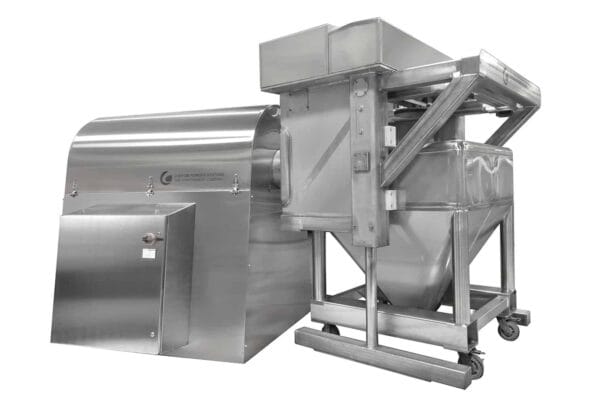

Mac knew there was something special about how these two companies worked together on this project. Each brought a skill-set the other didn’t have. Russ Krainiak says “It was the right fit because his company was good at powder, and ours was good containment. It gave us a strength a lot of companies don’t have.”

Combining Custom Powder with Integrated Containment did more than merge two talented companies. It made it easier for clients to see the work without having to travel all over the country.

“Nobody just buys an isolator,” says Ronnie Harris, Director of Engineering. “They want it integrated. They want it automated. ICS and CPS together has given us more solutions for the customer than we had by ourselves.”

Food and pharmaceutical companies are requiring their products remain free of contaminates, so having the ability to both blend and contain the product in an aseptic environment is crucial. It allows CPS/ICS the ability to take on larger projects with an even higher level of reliability than before.

According to Mac, “Our healthcare system is going to change incredibly in the next 10 years, and most of it will be done in isolation.”

Being able to take on projects as big and as out-of-this-world as a glovebox handling moon rocks for NASA—and as small as fixing it so the final cracker tastes as fresh as the first—means Custom Powder Systems and Integrated Containment Systems are one company ready to solve any challenge.

What can we invent for you?

Contact us here or call (417) 868-8002